Mango Pulp Processing Line

Request a Quote

The mango pulp processing line creates natural mango pulp from fresh mangos. The concentrated pulp retains a brix of 28 to 30% and is packed into 220L asetic bags or A10 tin cans.

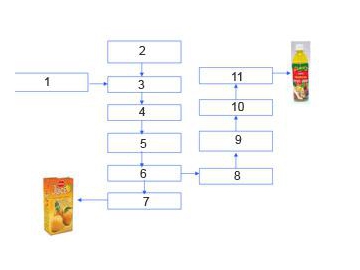

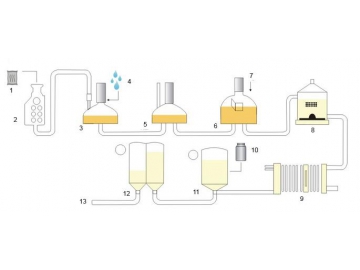

Flowchart

1. Fresh mango

2. receiving

3. Washing and sort

4. De-stoner

5. Pre-heating

6. Pulper and finisher

7. 2 effect Evaporator

8. Tubular sterilizer

9. Aseptic filler

Equipment List

| Model | Equipment name | QTY |

| JD-EV | Fresh mango receiving tank/Elevator | 1 |

| JD-WS | Washing machine | 1 |

| JD-SR | Sorting machine | 1 |

| JD-CR | De-stoner | 1 |

| JD-ST | Storage tank | 1 |

| JD-SCP | Pump | 1 |

| JD-PH | Pre-heater | 1 |

| JD-PP | Pulping machine | 1 |

| JD-ST | Storage tank | 1 |

| JD-VEORTOR | Vacuum evaporator | 1 |

| JD-TS | Tube-in-Tube sterilizer | 1 |

| JD-ASPTCF | Aseptic filler | 1 |

Capacity

| Model | Input Fresh mango per day 24 hours | Final Brix |

| 1 | 60t/day | 28-30% |

| 2 | 90-120t/day | |

| 3 | 240t/day | |

| 4 | 360t/day | |

| 5 | 500t/day | |

| 6 | 600t/day | |

| 7 | 800t/day | |

| 8 | 1000t/day |

As a China-based mango pulp processing line manufacturer and supplier, we also provide beer brewing equipment for beer bar, milk powder production line, cashew processing equipment, pasteurization milk/yoghurt production line, and more.

Related Names

Mango Pulp Production Line | Flavoring Mango Jam Making Equipment | Mango Chutney Production Plant | Dessert Mango Pulp Manufacturing Process

Related products

Send Message

Most Recent

More

Other Products

Videos