Application

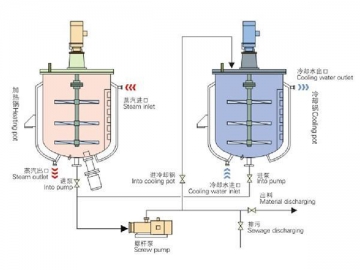

Homogenizing mixer machines are important pieces of equipment in cosmetics manufacturing factories especially for shampoo and detergent products such as liquid shampoo and detergent, bath cream, facial cleaner, hand lotion and so on. The mixer system has the function of mixing, dispersing, heating, freezing, discharging and defoaming.

Operating condition

Control system: TN-C-S system

Water source: reverse osmosis water

Motive power supply: 380VAC (±10%)50-60Hz

Control power supply: 220VAC (±10%)50-60Hz

Input of steam: DN25 steel pipe

Output of freezing water: DN32 steel pipe

Input of freezing water: DN32 steel pipe

Discharge hole: DN63 steel pipe

Technical parameter

JBJ-100L homogenizing mixer machine| Capacity (L) | Power of Stir motor | Rotate speed of stir motor (r/min) | Power of homogenizer motor | Rotate speed of homogenizer motor (r/min) | Thickness | Heating type |

| 100 | 0.75kw | 0-65 | 1.5kw | 3000 | 4mm | Steam or electric |

| Capacity (L) | Power of Stir motor | Rotate speed of stir motor (r/min) | Power of homogenizer motor | Rotate speed of homogenizer motor (r/min) | Thickness | Heating type |

| 200 | 1.5kw | 0-65 | 3kw | 3000 | 6mm | Steam or electric |

| Capacity (L) | Power of Stir motor | Rotate speed of stir motor (r/min) | Power of homogenizer motor | Rotate speed of homogenizer motor (r/min) | Thickness | Heating type |

| 500 | 2.2kw | 0-65 | 4kw | 3000 | 6mm | Steam or electric |

| Capacity (L) | Power of Stir motor | Rotate speed of stir motor (r/min) | Power of homogenizer motor | Rotate speed of homogenizer motor (r/min) | Thickness | Heating type |

| 1000 | 3kw | 0-65 | 7.5kw | 3000 | 6mm | Steam or electric |

| Capacity (L) | Power of Stir motor | Rotate speed of stir motor (r/min) | Power of homogenizer motor | Rotate speed of homogenizer motor (r/min) | Thickness | Heating type |

| 1500 | 4kw-5.5kw | 0-65 | 11kw | 3000 | 8mm | Steam or electric |

| Capacity (L) | Power of Stir motor | Rotate speed of stir motor (r/min) | Power of homogenizer motor | Rotate speed of homogenizer motor (r/min) | Thickness | Heating type |

| 2000 | 5.5kw | 0-53 | 11kw | 3000 | 8mm | Steam or electric |

| Capacity (L) | Power of Stir motor | Rotate speed of stir motor (r/min) | Power of homogenizer motor | Rotate speed of homogenizer motor (r/min) | Thickness | Heating type |

| 3000 | 7.5kw | 0-53 | 15kw | 1500 | 10mm | Steam or electric |

| Capacity (L) | Power of Stir motor | Rotate speed of stir motor (r/min) | Power of homogenizer motor | Rotate speed of homogenizer motor (r/min) | Thickness | Heating type |

| 5000 | 11kw | 0-53 | 22kw | 1500 | 10mm | Steam or electric |

Homogenizing mixer system is composed of a heating thermostat system, mixing pan, motor, speed reducer, control system, and processing platform.

Feature

1. Our homogenizing mixer machine has three mixing methods including an upper homogenizer, bottom homogenizer and internal and external circulation homogenizer.

2. The whole system adopts stainless steel structure and the contacted parts is made from SUS316L while other parts is made from SUS304. The tank and pipe is mirror polished meeting the requirement of GMP.

3. This homogenizing mixing machine can dissolve quickly AES, AESA, LSA and other indissolvable materials.

4. The tank of mixer is easy to clean and discharge the material, which can discharge directly or be equipped with deliver pump.

Safety production system

1. The equipment will automatic stop when mixing and homogenizing overloading or overvoltage.

2. Our mixer is also equipped with automatic discharge pressure function in order to prevent steam pressure of tank interlayer excess set pressure.

3. It will automatic drain when the pressure of emulsifying vessel freezing water exceeds the setting value.

4. The electrical control system is equipped with scram button to shut down in emergency circumstances.

5. The equipment rack and electricity box and marked place in processing platform are all labeled security identifier

Equipment production field Yuxiang as a leading homogenizing mixer machine manufacturer and supplier, mainly provides emulsion homogenizer for cosmetics manufacturing factory and household chemical manufacturing factory. Our company offer complete lotion and cream process line including mixing, agitating, dispensing, emulsifying, homogenizing, filling and sealing as well as custom solutions. For the different types of materials like lotion, cream, ointment products, our homogenizing machines can be designed and configured in customer needs.