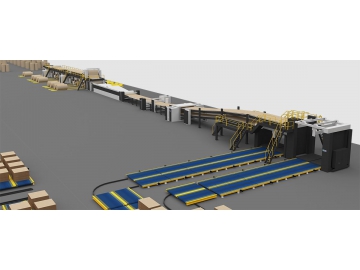

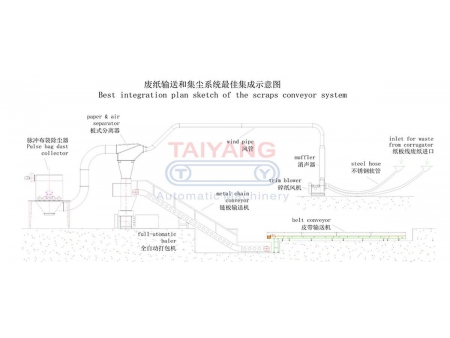

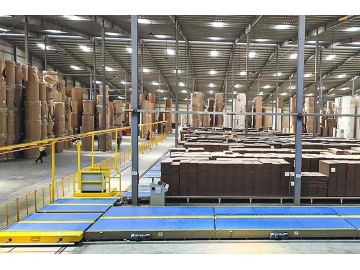

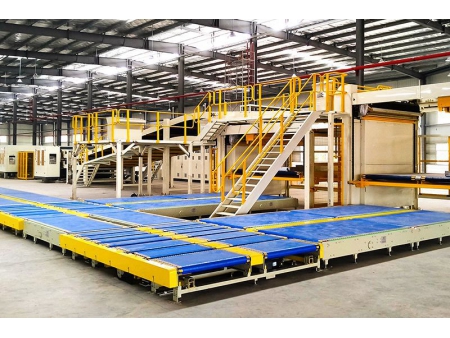

Corrugated Cardboard Conveying System

Corrugated Cardboard Conveying System

- Corrugated cardboard conveying system employs conveyors and RGVs (Rail Guided Vehicle) to handle transportations of corrugated cardboards between processes of production and storage in a high effiency manner.

- Configurations of control system is customizable to fit certain situations, and realize the optimal automated intralogistics efficiency.

-

- Transfer Cart

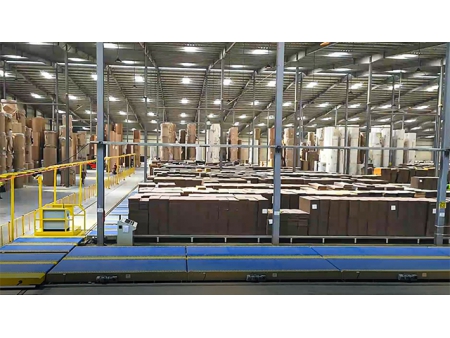

Traffic-jam-free work-in-progress storage with great efficiency

High-performance transfer cart offers excessive extra efficiency for your work-in-progress storage. With maximum speed up to 120m/min and laser rangefinders equipped, the cart can transport the stacks precisely to where they are needed. Safety is another point to emphasis here – the cart equips two laser scanners each on the front sides, with which a controller is designed so that manual operation is supported as well.

-

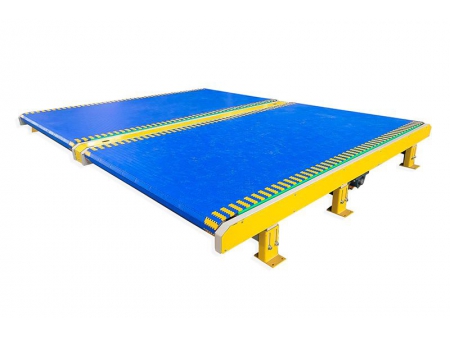

- Buffer Conveyor

Stack transportation is stable and uninterrupted

Stack transportation is proceeded with our tested conveyor. The conveyor equips modular plastic chains made of acetal to achieve high stability and efficiency.

Advantages: Low-maintenance, convenient service; Frequency-controlled drive; Space usage optimized by double occupancy of storage lanes; No sheet-walk effect; Waste caused by damage is reduced; Safe operation.

-

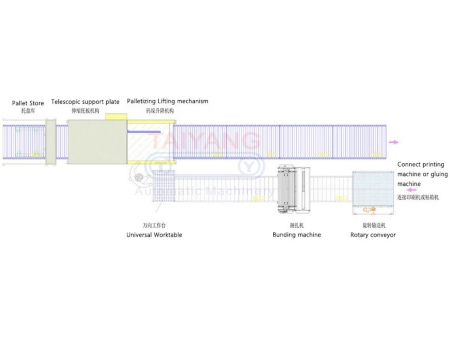

- Custom Conveyor

Whatever in the way, our designers can handle

Many issues must be considered when designing a conveying path, some devices may have strict demands on local conditions, and obstacles like pillars might exist in the path. But don’t worry, our expert and experienced team can offer you the very optimal design. Whether turning devices, right angle conveyors are needed or not, we can plan the right elements and arrange the optimal path for you.

- Chassis: the frame structure is mainly welded with 12#/ and 10# steel channels; Polyurethane coated rubber wheel;

- Total power: 6.25 ~ 11.5kW, customization upon request;

- Conveyor type: plastic modular chain/roller;

- Optional conveyor specification: 2500L*2500W/2600L*2500W/2900L*2500W (customization upon request)

- Safety: mechanic anti-collision system included, optional radar detection;

- Power supply mode: overhead or underground power line;

- Automation: full automatic or manual driving;

- Speed: 120m / min.

As a professional manufacturer of corrugated board plant auxiliary equipment, Taiyang offers high performance transfer carts with conveyor belt or conveyor roller top. These material handling carts are engineered in response to the specific needs of in-plant corrugated cardboard transport between cardboard lines, printing machines and carton box making machines. This kind of industrial delivery cart can ideally solve cardboard box manufacturers' challenges for fast cardboard feeding and unloading, therefore effectively improving productivity with quick changes after an order has been completed.

This transfer cart is mainly consisted of chassis and conveyor.

- Chassis

Transfer cart is a conveying equipment using a conveyor top that is installed on a chassis, also known as traveling base. It allows quick and effective transferring of corrugated boards from one line to the another, automatic transfer cart or manual transfer cart can be offered to suit your production applications. Primarily designed for cardboard box manufacturing, these transfer carts are extensively used for transporting cardboard from corrugated line to printing machine, packaging machine or other cardboard processing equipment. - Conveyor

Transfer carts are configured with conveyor belt or roller top attached to the chassis. With functions of corrugated cardboard loading and unloading, conveyor deck of the transfer cart can pick up items from one conveyor, and transport them to the desired conveyor, playing an essential role in connecting conveyors at each process end.

- Total power: 0.75~2.2kW (customized)

- Conveyor type: Plastic modular chain/belt/roller

- Speed: 18-60m/min

- Optional conveyor specification: 1600L*1500W/2500L*2500W/3600L*2500W (customization upon request)

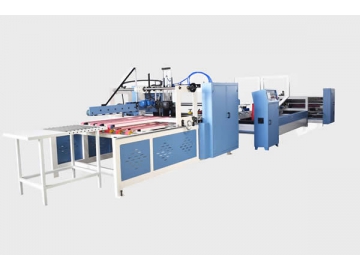

Our light duty modular belt conveyors are conveyor system modules with modular chain belts, with the capability for long-distance transportation of cardboards and enabling multiple processes to be carried out during the conveying. This light duty modular belt conveyor allows cardboards to be transported through horizontal, vertical and inclined paths. It can overcome the shortcomings of belt tears, wear cuts, holes and corrosion that are often occur in conventional belt conveyors. This modular belt conveyor is difficult to run off due to it employs a modular chain belt driven by sprockets, giving users a safe and effective conveying method with easy maintenance. In addition, the conveyor belt is thick enough to resist wear cut, collision, oil and water, thus greatly reducing maintenance costs.

The conveyor belts can be made different materials to adapt to various conveying tasks and to accommodate the specific requirements of corrugated cardboard conveying applications.

- Long service life of modular chain belt, with exclusive wear resistance;

- Easy to clean and maintain;

- Excellent resistance to tearing, piercing and corrosion;

- 1100W*3000L/4000L/5000L

- 1200W*3000L/4000L/5000L

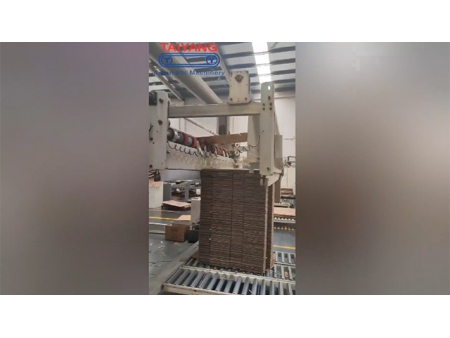

We know that production safety and product quality are the two most important criteria that matters to corrugated cardboard manufacturers. To fulfill market needs of high productivity and reduce cardboard damage that frequently occurs in conventional conveying systems, we offer heavy duty modular belt conveyor to conduct cardboard transporting operations from corrugated board line through to final carton box warehousing. It is a safe and reliable solution alternative to traditional conveying methods by means of corrugated cardboard pallets.

This corrugated cardboard conveyor can not only ensure eco-friendly and smooth conveying operations, but also protect cardboard from being damaged during conveying process. This minimizes the material waste and reduces manufacturing costs, while greatly improving the quality of corrugated cardboard.

- Guaranteed safety of operator at working area;

- Minimal material wastes during conveying;

- Stable stacking, low conveying cost;

- Robust structure, ensuring reliable transporting;

- Long service life, less maintenance cost;

This is a conveyor system integrated with straight conveyor (X-axis conveyor) and roller conveyor with lift (Y-axis conveyor). Therefore, it's also can be named XY conveyor. It's easy to construct automation line by allowing direction change to the conveyor.

- Straight conveyor: optional with plastic modular belting or roller

- Total power: 2.25 kW (or customized)

- Conveyor with lift: optional with plastic modular belting or chain

- Lift: air bag

- Optional conveyor specifications: 2500L*2500W/3600L*2500W (or customized)

- Chassis: the frame structure is mainly welded with 10#/ and 8# steel channels; Polyurethane coated rubber wheel;

- Conveyor type: Plastic modular belting/roller;

- High safety: safety fence,1500mm high

- Rotation angle: 0°-90 ° / 180°

- Speed: 32m/min

- Optional conveyor specification: 2500-3000L*2500-3600W (or customized)

Point to point transportation between conveyors, to maintain intralogistics performance and efficiency while reducing the quantity of conveyors or reserved paths for conveying.

- Chassis: the frame structure is mainly welded with 12#/ and 10# steel channels; Polyurethane coated rubber wheel;

- Total power: 2.75kW, customization upon request;

- Conveyor type: plastic modular chain/roller;

- Safety: optional radar detection;

- Power supply mode: overhead or underground power line;

- Automation: full automatic;

- Optional conveyor specification: 2500-3000L*1500~2500W (customization upon request)

- Chassis: the frame structure is mainly welded with 12#/ and 10# steel channels; Polyurethane coated rubber wheel;

- Conveyor type: plastic modular chain/roller

- Rotation angle: 0°~360°

- Speed: ≤ 32m/min

- Turntable specification: ⌀ 2500/3300 (or customized)

- Total power: 2.05kW or customized

- Conveyor speed: 35m/min

- Conveyor type: steel ball/roller type

- Rotation type: optional ball plastic modular belting or lift & rotate system

- Rotational speed: 90° in 2s

- Optional conveyor specification: 2000L*1600W/2500L*2500W (customization upon request)

- Total power: 0.75~2.2kW

- Conveyor type: plastic modular chain/roller

- Rotation angle: 0°-90°

- Conveyor specification: 1200mm Width, R1200/R2450 mm

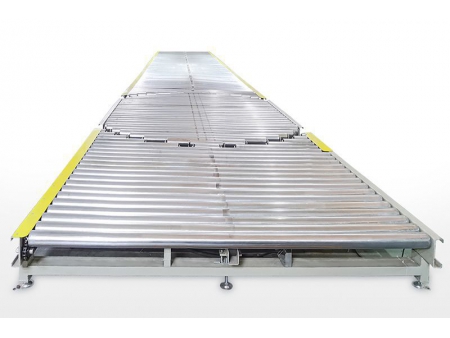

Gravity roller conveyor is a very cost-effective and versatile conveying system with extensive applications. Known for its ability for simplifying operations and enhancing productivity, this gravity conveyor is featured by high flexibility for moving corrugated cardboards throughout the conveying system, allowing more goods to be transported simultaneously over great distances in the workplace while significantly reducing manual handling tasks. Our gravity roller conveyor can be made according to customers' specific needs for transporting corrugated cardboards of different lengths, widths and stack heights. The rollers of gravity conveyor are available in galvanized steel rollers and stainless steel rollers, which are firmly mounted in the painted steel frame.

- Side panel: 80L*30W steel C-profiles

- Roller size: 45mm*50mm/60mm*76mm/customized

- Conveyor width: 370mm/2400mm/customized

- Conveyor length: 3000mm/customized

- Chassis: mainly welded with 10# steel angles and 8# steel channels, with steel wheels

- Roller diameter: 45mm/50mm/60mm/76mm or customized

- Optional conveyor specification: 2500L*1600W/2500L*2500W (customization upon request)

- Conveyor frame: made using 50*59 square steel tube and 3mm steel plate

- Roller diameter: 50mm

- Conveyor specification: 1000L*1000W (customization upon request)

- The board dispenser is connected with conveyor on the stacking station of the corrugated cardboard production line, which is used for automatically placing base board before conveying cardboard stack. This avoids damage to the bottom of the stack, and provides protection of bottom edge, thus less waste generated.

- Rollers support the board, allowing for smooth board conveying.

- Adopting chain conveyor and block reduces damage to the board when it's pushed.

- Height limit ensures the board is delivered one by one.

- The automatic control system between corrugator line and board dispenser is fully integrated, making the board dispenser works synchronously with the stacking section.

In order to meet today's market demands of reducing material wastes, Taiyang's R&D department has developed a cardboard handling vacuum gripper system which is a manipulator system using suction pads, enabling the cardboard to be securely gripped without damaging the bottom of the cardboard. Therefore, the problem of cardboard damage during the lifting and transporting can be effectively solved. This vacuum gripper system can be pre-set to select and place wooden panel or paperboard on the conveyor of the stacker according to the cardboard size, thus protecting the cardboard at the bottom of the cardboard stack. During the corrugated cardboard conveying process using either roller conveyor or belt conveyor, this vacuum gripper system can provide a guaranteed protection against cardboard damage, while ensuring the quality of finished products and reducing material waste which translates to lower production costs.

Features- High automation level, can be connected to production management system for data exchange;

- Place a wooden panel under the cardboard stacks, reliable and simple;

- Long service life, less maintenance costs;

- Protect the cardboard at the bottom from being damaged, greatly reducing waste;

- The ball transfer table is used where product needs to be rotated or moved in more than one direction.

- Steel ball: 1-1.5 inch

- Specification: customized

Automatic pallet inserter system is intended to automatically load corrugated cardboard stacks on pallets made of wood, plastic or metal. It is an ideal solution for the automatic loading of cardboards from cardboard line to pallets.

Our automatic pallet inserter system is composed of a pallet inserter conveyor and a set of pneumatic stop gate. After wooden or plastic pallets are manually placed in the designated area for unloading, and then the pallet inserter conveyor either manually or automatically places the cardboard stacks on the pallets, after which the loaded pallets are transferred to downstream processing sections using forklifts or other material handling equipment.

- Drive system: motor 2.2kW

- Load capacity: 2000kg

- Applicable cardboard line: width of cardboard line 1.8m/2.2m/2.5m/2.8m (customizable)

- Cardboard sheet length: 2.5m/2.8m

- Usage: corrugated cardboard conveying and unloading

- Modular structure, fast installation;

- Stable and quick unloading in an orderly manner;

- Less consumption;

- Mainly constructed with 140*140 square tube and 18mm thick plywood;

- Drive system: pneumatic;

- Dimensions are suited to the size of pallet inserter conveyor