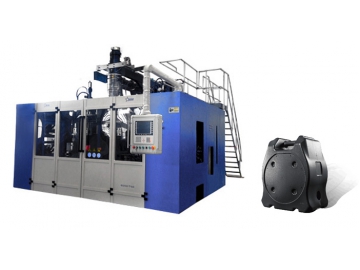

U Series Extrusion Blow Molding Machine

Application

Timey’s U series extrusion blow molding machine belongs to linear guide rail series, with hydraulic system, suitable for the production of 10L below plastic hollow products made from different materials, such as PE, PP, EVA , ABS, K-Resin(BS), TPU, nylon.

| Model | ...... | ...... | ...... | | | | |||||||

| Category | Single layer | Double layer | Double layer with view stripe | Triple Layer | Linear Guide Rail | ||||||||

| Max Volume(L) | 380mlx8 | ...... | 10L | 1 | ...... | 10 | 5 | ...... | 5 | 1 | 5 | 0.25 | 10 |

| Die Head No. | 8 | ...... | 1 | 4 | ...... | 1 | 1 | ...... | 2 | 2 | 2 | 6 | 2 |

| Center Distance (mm) | 70/80 | ...... | / | 85/100 | ...... | / | / | ...... | / | 120/125/130/140 | 250/280 | 70 | 280 |

| Net Weight(Kg) | 9000 | ...... | 9000 | 8500 | ...... | 9500 | 8500 | ...... | 8500 | 9000 | 11000 | 5000 | 12000 |

| Machine Dimension (l x w x h) | 4x4.6x2.6 | ...... | 4.3x3.2x2.6 | 3.8x3.6x2.45 | ...... | 4.3x3.2x2.6 | 3.8x3.6x2.5 | ...... | 3.8x3.6x2.5 | 4.2x4.7x2.7 | 5.6x3.9x3.4 with labeling | 3.5x3.3x2.2 | 6.2x3.7x4.7 |

| Min Clamping Distance of Mould(mm) | 250 | ...... | 230 | 200 | ...... | 230 | 200 | ...... | 200 | 200 | 230 | 160 | 230 |

| Clamping stroke(mm) | 200 | ...... | 350 | 250 | ...... | 350 | 250 | ...... | 250 | 200 | 390 | 150 | 290 |

| Extruder diameter of clamping unit (mm) | ...... | 78 | ...... | 127 | 80 | ...... | 78 | 120 | 190 | 31.4 | 196 | ||

| Extruder diameter of Extruder Unit (mm) | 75 | ...... | 75 | 65/45 | ...... | 75 / 55 | 65/45/25 | ...... | 65/45/25 | 75/55/45 | 75/55/30 | 65 | 85/65/30 |

| Extruder Motor Power(kw) | 30 | ...... | 90/105 | 15 / 5.5 | ...... | 22/11 | 15/5.5/2.2 | ...... | 15/5.5/2.2 | 30/11/5.5 | 30/7.5/5 | 15 | 30/15/2.2 |

| Max extrusion capacity | 120Kg/h | ...... | 22Kg/h / 30Kg/h | 60 / 14 | ...... | 90 / 30 (Kg/h) | 60/14/2(Kg/h) | ...... | 60/14/2(Kg/h) | 125/30/14(Kg/h) | 105/25/4 | 60 | 130/42/4 |

| Total power | 64.5kw | ...... | 58.5kw | 49.5kw | ...... | 77.2kw | 53.8kw | ...... | 61.2kw | 94.7kw | 99.5kw | 41.5kw | 104.3kw |

| Remarks: 1. The product listed is portion of our product. More models request, please asks for the Machinery Brochure. 2. Listed machine is for reference purpose. Machine can be produced according to clients' practical requirement. | |||||||||||||

Features

1.Adopting full-automatic intelligent computer control system with Chinese or English operating interface, it is easy to operate, set up and modify program.

2.Strengthened and hardened type screw stem with cold treatment have good wear resistant. According to the features of different plastics, different runner types can be designed with large extrusion volume.

3.With deep mirror finish inside the plastic extrusion dies, the curved runner is smooth without dead angle or carbon deposition. It is convenient for reloading, recoloring, slagging, dismantling and cleaning, and the wall thickness of the symmetrical part of the tube blank is very uniform.

4.The rigorous process ensures the overall parallelism of base, avoiding the guideway from dropping balls.

5.The dual proportional valves controls the oil flow speed and pressure, the reversing valve controls the flow direction and the deceleration valve is used for brakes. Thus, the movements are smooth and rapidly.

6.By using toggle clamping mechanism, even and constant mold clamping force is ensured due to simultaneous pressure on the front and back sides of platen center.

7.According to the features of different plastics, different screws are equipped: PE screw, PVC screw, high polymer screw, filling screw etc.

8.The lifting type extrusion platform is convenient to adjust the length of the preform.

9.CE security standard design, pay attention to users’ safety.

10.Japanese frequency changer is used to adjust the rotary speed of the screw, saving electricity and energy.

11.Automatic lubrication system, automatic alarm function

We offer plastic container making machines for manufacturing plastic bottles and containers. Our U series extrusion blow molding machine is suitable for making PE water bottles, polypropylene containers, EVA containers, etc. We have all the production resources to make plastic blow molding machines with custom made service, offering quality machines for making plastic food containers, cooking oil containers, medical containers, detergent bottles, chemical containers.