Die Spotting Press

Grinding during mold making, as well as repair after mold testing and multiple mold opening/closing processes on both male and female dies are a necessary process. When working with medium and large molds, a higher degree of an automatic, specialized die spotting process is incredibly important, as it reduces operation labor intensity and improves operation safety levels.

Shunxing has designed 5 die spotting press series with different structures in order to meet customer requirements. They can be used for the production and inspection of various molds, such as injection molds, die casting molds, stamping dies, glass dies, rubber dies, metallurgy dies and more. Our die spotting press is also applicable to cold press molding of large sheet areas in a number of industries, including automobiles, hardware and home appliances.

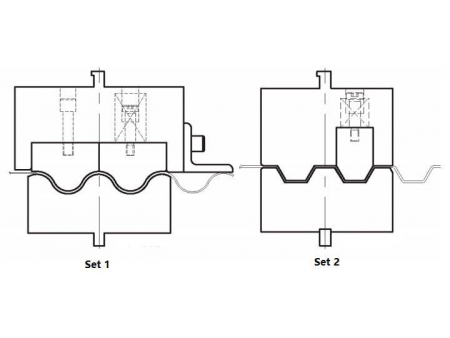

◆ Guide pillar structure

The guide pillar structure and elastic mold plate ensure the parallel mold adjustment is easier. This ensures a higher spotting precision.

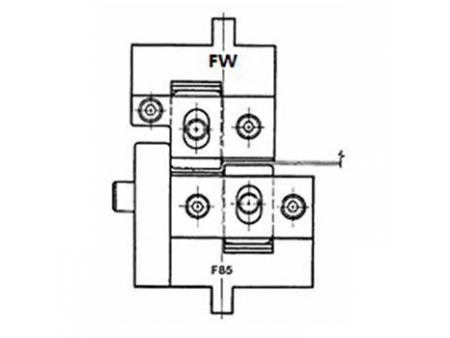

◆ Spotting oil cylinder

Four spotting oil cylinders ensure a more uniform mold plate force, with a smaller deformation coefficient.

◆ Complete protective measures

Mechanical safety ensures operation of the mold and machine is safer.

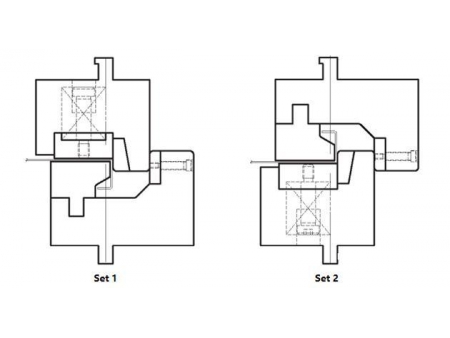

◆ The lower working table is equipped with a high precision positioning device and lifting device. The movement position of the mold base is determined by the MTS digital readout, ensuring a more accurate operation.

- Lower mold plate removing device

- Lower mold plate guiding device

- MTS digital readout

◆ It features practical and reliable fault detection, and will sound an alarm, as well as protect the mold in low pressure conditions.

◆ All the movable parts on this machine are equipped with graphite copper sheathing for guiding, and there is no need for oil lubrication, thus ensuring the machine cleanliness.