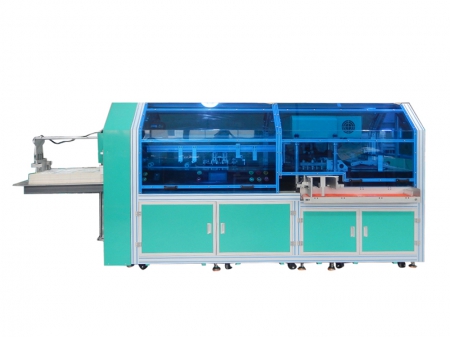

Automated Hole-punching and Creasing Machine, WT-007PCM

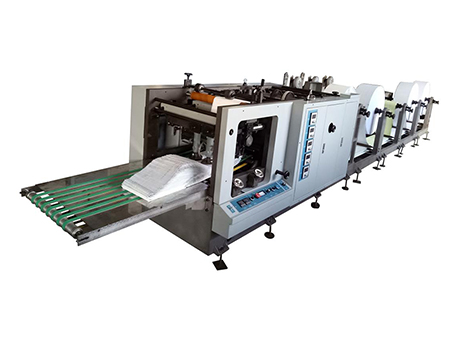

Our automated hole-punching and creasing machine is typically used to produce hang tags, labels, RFID products, it is applicable to process a variety of materials such as paper card, PVC, ABS, PET, PVC/ABS composite materials with a thickness range of 0.2mm-2.0mm. Servo motor drives timing belt to allow sheets to be precisely fed. Double card magazines for card feeding greatly improve working efficiency.

| Power supply | AC 380V/50 HZ | Card size | Customized |

| Total power | 2.0KW | Control | PLC control servo system |

| Air source | 6 kg/cm2 | Operators needed | 1 |

| Air consumption | Approx. 80L/min | Dimension | L1650*W680*H1600MM |

| Positioning accuracy | ±0.1mm | Card thickness | 0.2mm~2.0mm |

| Weight | Approx. 400KG | Mold | 1 or 2 optional |

| Applicable card materials | Paper card, PVC, ABS, PET, PVC/ABS composite materials, etc. | Productivity | 10000PCS/H |

- Productivity: 10000PCS/H

- Card size: Customized

- Positioning accuracy: ±0.1mm

- Card thickness: 0.2mm~2.0mm

- Dimension: L1650*W680*H1600MM

- Weight: Approx. 400KG

- Power supply: AC 380V/50 HZ

- Total power: 2.0KW

- Control: PLC control servo system

- Air source: 6 kg/cm2

- Operators needed: 1

- Air consumption: Approx. 80L/min

- Mold: 1 or 2 optional

- Applicable card materials: Paper card, PVC, ABS, PET, PVC/ABS composite materials, etc.

-

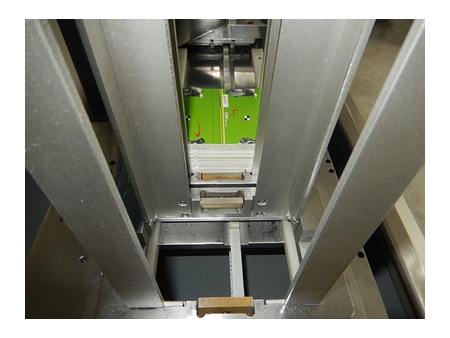

- Card magazines

Double card magazines are changeable to increase production efficiency while make the card stacking process easier;

-

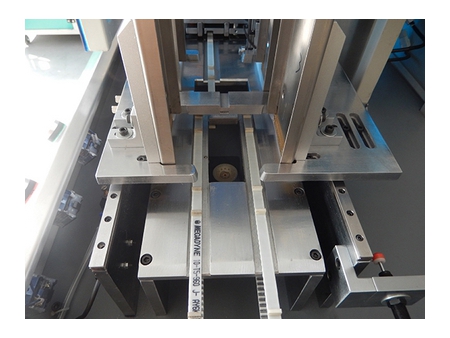

- Servo motor & timing belt assembly

Timing belt is driven by servo motor to transfer cards to the designated position, providing fast positioning, high precision and adjustable speed;

-

- Inspection unit

Sensor determines the quantity of sheets to feed each time by adjusting the thickness of single sheet, and the alarm will be actuated in the event of abnormal operation;

-

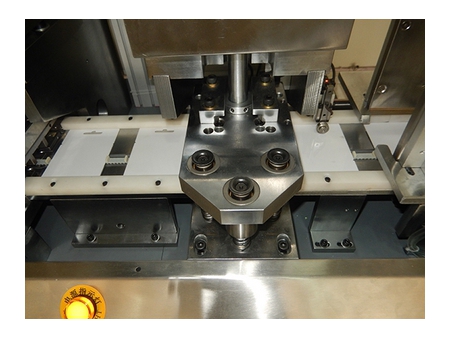

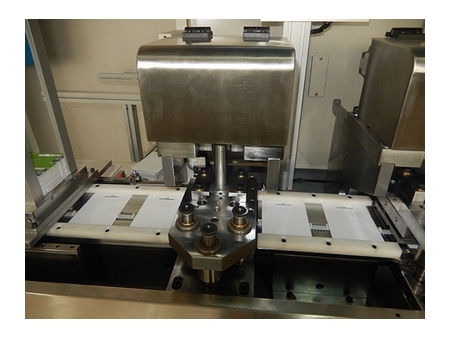

- Servo punching & creasing unit

High torque servo motor is adopted to guarantee stable work pressure and low noise level; The unit can implement punching and creasing simultaneously, or independently perform one of these two processes;

-

- Card collection unit

Double card magazines work alternately, enabling card collection to be easier and improving production efficiency;