KTNF53-4/66-320 Jacquard Loom(Narrow Fabric Weaving System) Electronic jacquard loom, ribbon weaving loom

Comtech provides the customized narrow fabric weaving machine according to the number of tapes, width and hook required by the customer.

| Model | 8/27 | 6/42 | 4/66 |

| No. of Hooks | 128-384 | 128-384 | 128-384 |

| Tape Lines | 8 | 6 | 4 |

| Reed Width | 27mm | 42mm | 66mm |

| Max. Weaving Width | 25mm | 40mm | 62mm |

| No. of Heald Frame | 12 | 12 | 12 |

| Repeat Length | 1:8/16-32 | 1:8/16-32 | 1:8/16-32 |

| RPM | 1250r/min | 1250r/min | 1250r/min |

| Machine Width | 980mm | 980mm | 980mm |

| Max. Machine Height | 2600mm | 2600mm | 2600mm |

| Min. Machine Length | 3000mm | 3000mm | 3000mm |

| Net Weight | 890KG | 890KG | 890KG |

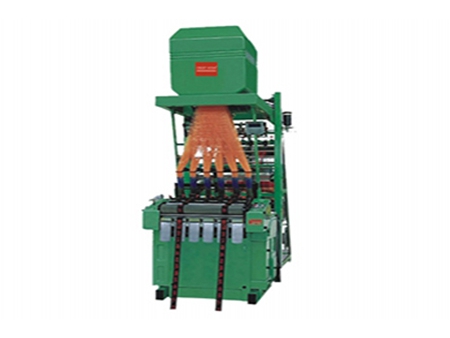

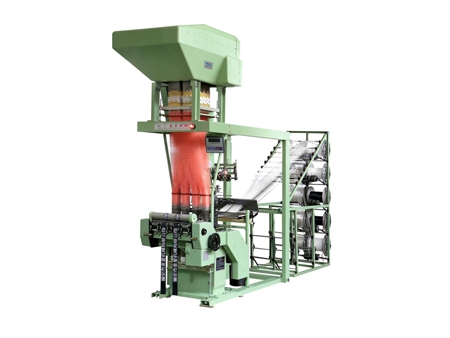

Narrow fabric loom is suitable for light to medium-weight elastic and non-elastic narrow fabrics. The weaving machine is designed with 53cm in width, and can weave 4 tapes at one time, each with max. width of 66mm and hooks of 320.

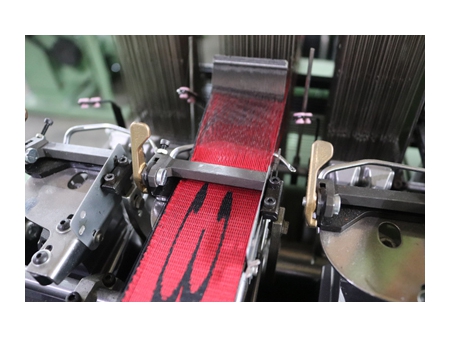

The KTNF53-4/66-320 jacquard loom is a specialized piece of equipment for manufacturing narrow fabrics in a variety of jacquard patterns, including elastic or non-elastic woven tapes with wide applications in underwear lace bands, elastic tapes, curtain tapes, backpack belts, headbands, and more. The jacquard pattern is created by 320 warp threads and 12 heald frames.

After more than 30 years of experience in weaving machine parts processing, Comtech is an expert on ribbon weaving machine structure and principles, and has mastered the precise manufacturing technology. We control the accuracy of each component, and ensure all combinations run smoothly. Due to this, our computerized jacquard loom maintains a stable operation status at higher production speeds, and avoids yarn jumping, as well as improves the output and finished product rate.

KTNFM53-4/66-768 Jacquard Loom(Narrow Fabric Weaving System) Computerized jacquard loom, ribbon weaving loom