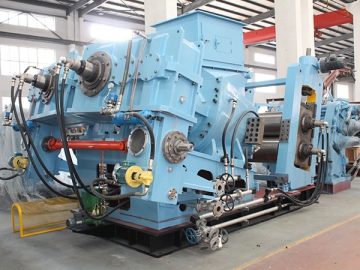

Internal Mixer/ Banbury Mixer

Characteristics

1. Internal mixers are primarily used for plasticating, mixing and final mixing of rubber and plastic materials.

2. Different rotors are used to accommodate different mixing processes. Customers can choose rotors based on what they need.

3. Rotors, mixing chamber, unloading gate, and counter weight can be cooled using a water cooling system with a large cooling area. In addition, a water temperature control system is also equipped to efficiently guarantee the quality and stability of the rubber obtained.

4. Numerous parts, including the rotor surface, internal wall of the mixing chamber, surface of the unloading gate, and surface of the counter weight will come into contact with mixed materials. To prevent corrosion, they are coated with a wear resistant alloy or hard chrome, thus preventing pollution and reducing overall wear.

5. The rotor ends are sealed with a hydraulic sealing device, which features an adjustable sealing pressure and high reliability.

6. The ram can be pneumatically driven or hydraulically driven to ensure the constant pressure on the mixed materials.

7. The drop door achieves discharging using a drop ping method. The unloading gate is driven by a combination of the gear rack, gear wheel, and hydraulic cylinder, which work together to ensure the tight locking and self-locking performance, as well as overall sealing effect.

8. The transmission system is stable, low noise, and has a long service life. The structure and speed of the transmission mechanism can be customized based on customer requirements.

9. PLC control systems are most often used, and achieve both automatic and manual control. The control system is easy to operate, has a high disturbance capacity, safe and reliable signal detecting capacity, and a feedback function. It is able to effectively control the rubber quality and ensure the mixer operates in normal methods. The control scheme is carried out with 1 of 3 choices: time, temperature, or simultaneous time and temperature. The control system can be designed according to specific customer requirements.

- Tangential rotor

Intermeshing rotor

Intermeshing rotor

| Model | ||||||||

| Total Volume of Mixing Chamber (L) | 26.5 2-wings | 50 2-wings | 80 2-wings | 110 2-wings | 147 4-wings | 253 2-wings | 250 4-wings | 425 4-wings |

| Working Volume of Mixing Chamber (L) | 20 | 37.5 | 60 | 82.5 | 110 | 140 | 188 | 319 |

| Rear Rotor Rotating Speed (r/min) | 40 | 40 | 40 | 40 | 4~40 | 20 | 4~40 (6~60) | 6~60 |

| SPEED RATIO OF ROTORS | 1:1.16 | 1:1.15 | 1:1.15 | 1:1.15 | 1:1.16 | 1:1.16 | 1:1.17; 1:1 | 1:1.15;1:1 |

| Compressed Air Pressure (Mpa) | 0.6~0.8 | 0.6~0.8 | 0.6~0.8 | 0.6~0.8 | 0.6~0.8 | 0.6~0.8 | 0.6~0.8 | 0.6~0.8 |

| Compressed Air Consumption (m³/h) | ~70 | ~80 | ~100 | ~230 | ~300 | ~120 | Hydraulic ram | Hydraulic ram |

| Cooling Water Pressure (Mpa) | 0.3~0.4 | 0.3~0.4 | 0.3~0.4 | 0.3~0.4 | 0.3~0.4 | 0.3~0.4 | 0.3~0.4 | 0.3~0.4 |

| Cooling Water Consumption (m³/h) | ~10 | ~15 | ~25 | ~35 | ~45 | ~23 | ~100 | ~150 |

| Driving Motor Power (kw) | 55 | 90(110) | 220 | 250(280) | 500 | 250 | 1250(1500) | 2 ×1250 |

| Overall Dimensions (mm) | 4460 ×3225×3200 | 5560 ×2510×3200 | 5800 ×2560× 4200 | 6620 ×2850×4400 | 8000 ×3300×5260 | 7100 ×3905×4953 | 8700 ×4320× 6160 | 10800 ×4960×7040 |

| Gross Weight (Excluding Main Motor) (t) | ~7 | ~14 | ~22 | ~26 | ~36 | ~35 | ~50 | ~76 |

| Model | | | ||||||

| Total Volume of Mixing Chamber (L) | 47 Intermeshingrotor | 87 Intermeshingrotor | 140 Intermeshingrotor | 160 Intermeshingrotor | 200 Intermeshingrotor | 250 Intermeshingrotor | 320 Intermeshingrotor | 420 Intermeshing rotor |

| Working Volume of Mixing Chamber (L) | 30 | 57 | 91 | 104 | 130 | 162 | 208 | 273 |

| Rear Rotor Rotating Speed (r/min) | 6~60 | 6~60 | 6~60 | 5~50 | 6~60 | 4~40 | 6~60 | 6~60 |

| SPEED RATIO OF ROTORS | 1:1 | 1:1 | 1:1 | 1:1 | 1:1 | 1:1 | 1:1 | 1:1 |

| Compresed Air Pressure (Mpa) | 0.6~0.8 | 0.6~0.8 | 0.6~0.8 | 0.6~0.8 | 0.6~0.8 | 0.6~0.8 | 0.6~0.8 | 0.6~0.8 |

| Compressed Air Consumption (m³/h) | Hydraulic ram | Hydraulic ram | Hydraulic ram | Hydraulic ram | Hydraulic ram | Hydraulic ram | Hydraulic ram | Hydraulic ram |

| Cooling Water Pressure (Mpa) | 0.3~0.4 | 0.3~0.4 | 0.3~0.4 | 0.3~0.4 | 0.3~0.4 | 0.3~0.4 | 0.3~0.4 | 0.3~0.4 |

| Cooling Water Consumption (m³/h) | ~15 | ~25 | ~40 | ~50 | ~60 | ~100 | ~120 | ~150 |

| Driving Motor Power (kw) | 280 | 520 | 720 | 750 | 1100 | 1250 | 1680 | 2 ×1250 |

| Overall Dimensions (mm) | 6200 ×2435×3750 | 7500 ×2870×4700 | 8200 ×3100×5275 | 8600 ×3800×5730 | 9000 ×4500×6200 | 9500 ×4800×6330 | 9800 ×34850×6500 | 11500 ×4960×7400 |

| Gross Weight (Excluding Main Motor) (t) | ~15 | ~23 | ~29 | ~39 | ~45 | ~56 | ~60 | ~78 |

Note:The machine is divided into left or right diven.